Highlights

- Self-healing materials repair damage autonomously using microcapsules and dynamic chemical bonds.

- Electronics with self-repair pathways can restore conductivity after fractures.

- Self-healing batteries may extend lifespan and improve safety by reducing dendrite failure.

- Commercial adoption is limited by cost, scalability, and the speed of self-repair.

Cracked screens, frayed cables, degraded batteries, modern technology fails not because it is obsolete, but because it breaks. For decades, durability has been treated as a trade-off against thinness, weight, and aesthetics. In a world of sealed devices and rapid upgrade cycles, breakage has become a feature of the system rather than a flaw. Self-repairing materials challenge that assumption.

In 2026, materials that can detect damage and repair themselves are no longer confined to science fiction or academic papers. They are emerging in coatings, polymers, electronics, and energy systems, offering a vision of technology that heals instead of fails. The implications are profound. If devices can repair micro-cracks, electrical breaks, or structural stress in real time, the entire logic of product lifespan, sustainability, and repairability changes.

What Are Self-Repairing Materials?

Self-repairing and self-healing materials are those that get the damage repaired, and at the same time, the function is restored, with no external help involved. The traditional methods of repair, where the tools, human skill, or replacement parts are needed, are completely different from the self-healing systems, which automatically get activated as soon as the damage is done.

This is done in various ways and by different methods. For instance, some materials make use of microcapsules that contain healing agents, which are released when a crack forms, thereby sealing the damage with the substances that harden. Other materials are based on reversible chemical bonds that break when the material is stressed and that are re-formed when the conditions of stability are reached again.

The same principle can be applied in electronics, where self-healing can refer to the conductive pathways that reconnect after being cut, thus restoring the electrical continuity without the need for soldering done by hand. All these efforts aim at achieving resilience, recovery, not invincibility.

From Structural Materials to Smart Electronics

Structural materials are the first area of application, such as concrete and polymers, in building and aerospace. Self-healing technology has penetrated deep into the materials used for making bridges, aircraft parts, and pipelines, as these are costly and hazardous. The materials that allow repair of micro-damages can really bring about a huge drop in maintenance expenditure and an influx of safety. Thus, the logic behind this has already been laid down in consumer technology.

Foldable electronics, wearables, and soft robotics are the three main forces of self-healing conductive materials in the market. Stretchable circuits, incorporated in the smart fabrics or health monitors, have to endure constant bending and stretching. The self-repairing conductors facilitate the devices to go through the stress and yet not fail. The change from industrial materials to consumer electronics is a big step, both in terms of scale and of ambition.

Microcapsules and Smart Polymers: How Healing Happens

One among the self-healing methods that is the most developed and has reached the highest level of maturity is the one where microcapsules are integrated into a material. The moment damage appears, the tiny capsules get ruptured, and the liquid or gel that was encapsulated fills up the crack and then becomes solid.

This technique is very effective when used on coatings and structural polymers. Scratches in protective layers can seal themselves, which stops moisture from coming in and causing corrosion.

A different approach utilizes dynamic polymers that have reversible molecular bonds. The bonds break when the material is stressed and reform when heat, pressure, or time allows it. In some situations, the only thing the material needs is to rest, while in others, a small thermal stimulus is applied to speed up the healing process.

In the case of electronics, the use of conductive polymers and liquid metal pathways allows the reconnection of circuits after they have been cut or stretched, a capability that seems to be almost biological.

Self-Healing Electronics: A Quiet Revolution

Electronics are delicate by nature. Fine traces, solder joints, and connectors quit working long before processors or memory chips do. Self-healing electronics are designed with the delicate parts in mind.

Scientists have been able to make a circuit that gets back its conductivity after the circuit is cut, a battery that is able to come back to life after internal failure, and a sensor that can work under mechanical stress, to name only a few.

If we consider consumers, this means that there will be charging cables that will reconnect after being bent, displays that will be exempt from micro-fractures, and wearables that are still working even if they are subjected to daily abuse.

The good news is that these advances do not render the devices unbreakable; they do turn the failure into a gradual process rather than a sudden one.

Batteries That Heal Themselves

Batteries always seem to be the main culprits when it comes to device failures. Once the dreaded dendrite takes over the tree and branches apart, the electrodes lose their effectiveness, and the next thing you know, an internal short circuit is all that is left. All these problems combined lead to constant replacement and the risk of fires in the vicinity.

Self-healing battery materials seek to solve these problems through their internal repair mechanism. Among them are polymers that close micro-cracks in electrodes, or electrolytes that thwart dendrite growth. The combination of these solutions will not only prolong the life of the batteries but also make them safer to use.

Moreover, the economic and environmental impact of such advances would be enormous in the case of electric vehicles, grid storage, and portable electronics.

Durability Meets Sustainability

Probably the most compelling argument for the adoption of self-repairing tech is sustainability. The longer life of a device means less electronic waste, and consequently a decrease in resource extraction and the associated carbon emissions from manufacturing.

In the case of a smartphone that is able to last six or seven years instead of three, the environmental impact is significantly lower, regardless of how complicated its materials are.

Self-healing materials are naturally in tune with the goals of the circular economy. They decrease the range of the value chain from disposability to application life by lowering the need for replacements, repairs, and spare parts. In a market that is increasingly focused on its environmental impact, durability becomes a competitive advantage.

Why Isn’t Everything Self-Healing Yet?

Real limitations are the ones that self-repair technology is facing despite the impressive progress it made. The high price is one of the main hindrances. Self-healing materials are usually more costly to manufacture, and their large-scale production is more complex. For mass-market consumer devices, even a slight increase in price is of great significance.

Another problem is the repair time. Instantaneous healing is the case for some materials; others take minutes, hours, or even need specific conditions like heat. But consumers want instant recovery.

At the same time, repetition limits are also imposed. Some self-healing mechanisms are capable of working only once or a limited number of times, after which the healing agents get exhausted. Incorporating self-repair in small, sealed, and costly consumer electronics without losing their performance is still a complicated task.

The Aesthetic and Design Challenge

The self-healing principles can sometimes clash with design priorities. Ultra-thin devices have almost no space for microcapsules or layered materials. Glossy surfaces may turn healed spots into visible defects.

The question manufacturers face is whether consumers prefer perfection in aesthetics to long-lasting strength. This question is not only technical but also cultural. As durability becomes a more important factor in purchasing decisions, the design may move to portraying resilience rather than hiding it.

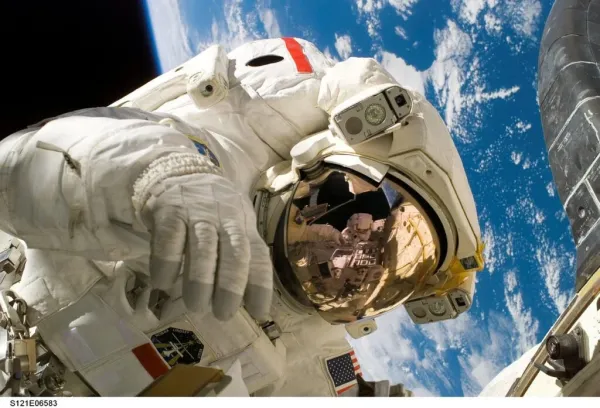

Infrastructure, Space, and Extreme Environments

The usage of self-repairing materials in consumer gadgets is the least used area where they can be applied. In space, repairs are virtually impossible. Satellites, space stations, and probes are greatly aided by materials that can heal themselves from micrometeoroid damage.

In the same way, self-repair can be applied in reducing maintenance costs and solving the problem of downtime in offshore platforms, pipelines, and renewable energy infrastructure in remote or even hostile areas.

Consumer markets have always been the last to be supplied with new materials and innovations. This is why they often adopt new materials beforehand and thus are the ones that end up funding the research that eventually trickles down to the consumer market.

Are We Moving Toward Technology That Cannot Be Destroyed?

The term “indestructible” continues to be a stretch, though. No substance can heal every harm done to it, and severe breakdowns will always be possible. The self-healing gadgets present the idea of graceful fading instead. The gadgets go through the process of failure more slowly, safely, and more predictably. Total replacement will not happen if the damage is small. This transition alters people’s desires. The device becomes a product that ages, and not something that suddenly dies out.

Consumer impact: repair culture reimagined

This phenomenon of self-solving materials might also metamorphose consumer’s perceptionof repair. Instead of the common dilemma of choosing between do-it-yourself repairs and costly replacements, many of the minor failures simply disappear. This could lead to a decrease in repair services, while manufacturers would face the opposite of demand for the long-term use of software updates and the availability of modular components. Thus, repairing culture does not disappear; it only transforms.

The path forward

By the year 2026, self-repairing materials will be at a crossroads. They have transitioned from being purely theoretical to a not-so-distant future. The adoption will happen first in premium devices, industrial systems, and specialized applications. As the prices go down and the technology matures, self-healing will become an expected feature rather than just a novelty. The main change may be among the consumers, and they will need to learn that technology will not just perform, but it will also recover, and this will take time.

Conclusion: Technology That Will Not Break

Self-repair materials are a new way of thinking about technology and its value. Rather than regarding damage as a terminal point, the new way is to have systems that communicate, adjust, and recover. This thinking couples longevity with eco-friendliness, and high performance with accountability.

Unbreakable gadgets might still be a dream,m but the magic of strong and self-healing technology is being realized. And, in a market flooded with throwaway gadgets, that very strength could be the most extreme innovation of all.

-

Mathura School Principal Suspended After Allegations Of Asking Students To Offer Namaz, Probe Ordered

-

World Wetlands Day: BNHS Flags Crucial Role Of MMR Wetlands In Protecting Mumbai From Climate Extremes

-

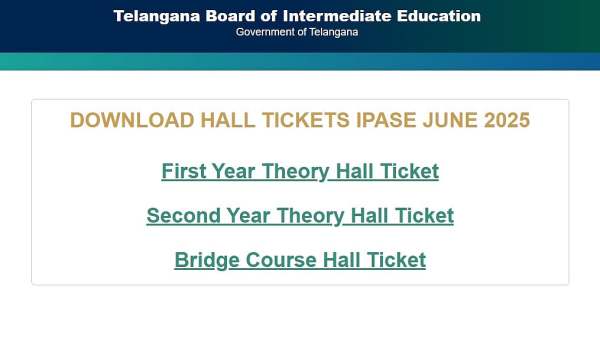

TS Inter Hall Ticket 2026 Out For 1st, 2nd Year At tgbieht.cgg.gov.in; Here’s How To Download

-

EAM S Jaishankar Embarks On 3-Day Crucial Visit To The United States Amid Strained India-US Relations

-

The Voice Nigeria Contestant Ifunanya Nwangene Dies At 26 After Being Bitten By Snake