In capital-intensive manufacturing businesses, scale often brings complexity. Managing that complexity, without slowing decision-making or diluting margins, has become central to how companies grow.

For Kairav Engineer, Executive Director at Astral Limited, the answer lies in structure, not instinct. “Corporate management taught me how to build structure without limiting creativity,” he said, a principle he applies across both business and large collaborative projects.

Structure As An Enabler

Drawing parallels between corporate execution and large-scale collaboration, Engineer said managing scale becomes manageable when roles and processes are clearly defined. “Clear guidelines, timelines, and smooth workflows helped contributors participate easily,” he noted, adding that discipline, not control, keeps large systems functioning. “Corporate life trains you to stay organised, prioritise effectively, and solve issues fast.”

That mindset has shaped Astral’s approach to growth, especially as the company expanded beyond its core piping business.

Diversification Without Losing The Focus

Astral’s move from CPVC pipes into adhesives, sealants, water tanks, and bathware was not a shift away from its core but an extension of it. “Plumbing remained the anchor,” Engineer explained, while adjacent categories helped expand the total market opportunity and reduce reliance on a single segment.

He pointed out that adhesives emerged as a critical stabiliser. “Adhesives, in particular, created a strong adjacent growth engine, supporting volumes even when piping demand fluctuated.”

Crucially, diversification was built around existing strengths. “The same distribution network, dealers, and contractor relationships could be leveraged to cross-sell multiple products,” he said, improving reach and brand recall across projects and retail counters.

Why Backward Integration?

With Astral’s CPVC resin plant beginning commercial production in January 2026, the company has taken a decisive step to control a key input. “Resin is a critical raw material,” Engineer said. “In-house production can reduce exposure to price swings, protect margins, and improve pricing stability.”

He added that supply security is just as important as cost. “It improves supply reliability during shortages or disruptions, helping us meet demand without production bottlenecks.”

According to Engineer, predictable costs create strategic flexibility. “With a lower and more stable cost base, we can either price competitively to gain market share or maintain pricing and earn better margins.” The move also strengthens negotiating power and supports consistent quality and product innovation.

Replacing Instincts With Data

As Astral scaled its workforce and footprint, traditional intuition-based decision-making was no longer sufficient. “Data-led working and analytics help Astral scale by improving efficiency, profitability, and speed of execution,” Engineer said.

Demand forecasting ensures the right production and inventory mix, while “channel analytics track dealer and distributor performance, helping target schemes and service where the impact is highest.” He noted that “pricing and SKU-level insights reduce margin leakage and optimise the product mix.”

Geographic data has also reshaped expansion plans. “It helps identify high-potential markets and reduces trial-and-error costs,” he said. On the factory floor, “manufacturing analytics improves uptime, reduces wastage, and strengthens quality consistency.”

Making Bathware Work For Traditional Dealers

Astral’s bathware expansion has required convincing hardware dealers to adopt design-led products, often perceived as risky. Engineer said the focus has been on simplifying the shift. “We make design-led selling easy and low-risk,” he explained.

The strategy includes “compact hero displays of best-selling styles,” dealer training to sell “complete bathroom solutions, not just price,” and tools such as “finish swatches, design boards, QR catalogues and videos.”

To reduce hesitation, Astral offers “higher margins, launch schemes and stock-rotation support,” while ensuring “strong after-sales and warranty handling to build trust.” Demand creation through designers, plumbers, and contractors ensures that “customers walk in asking for the brand.”

Alongside his corporate role, Engineer has also been involved in conservation-focused work. His exhibition, Ranthambhore – 50 Iconic Years, was a tribute to conservationist Valmik Thapar and brought together photographs contributed by hundreds of wildlife photographers from across the world. The project involved curating thousands of images into an immersive, multi-sensory experience, a process the engineer said relied heavily on structured coordination, clear workflows, and professional follow-ups, skills drawn directly from managing large-scale industrial and supply-chain operations.

-

How long does it take to forget the pain of separation? According to experts, anxiety will increase

-

Dungeshwari Temple Bihar: Where Lord Buddha did penance for 6 years

-

Just tap on the naked women, Google and Apple stores are still in force many such apps!

-

5G services now available in 99.9 percent districts of India

-

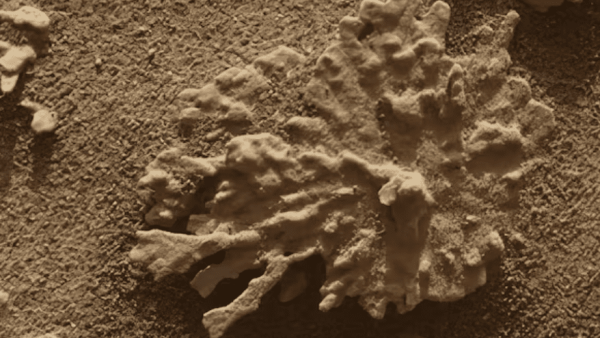

NASA’s Curiosity rover discovers “coral‑shaped” Mars rock like Egypt